We aim to contribute towards building a Nigerian capacity to meet the 21st century subsea structural integrity challenges.

SubseaRobotix brings to the Nigerian market a client-focused and solution-based approach to Subsea Engineering & Structural Integrity with technologies developed using ROVs and advanced subsea robotics.

At SubseaRobotix, we focus on delivering diverless robotic subsea solutions with a long term vision for EPCI project delivery at low cost and to specifications.

Quality Control, Efficiency, Cost Effectiveness

To be an Integrated company of choice driven by excellence across Oil and Gas value chain.

Going deeper for you with Diverless Integrity solutions

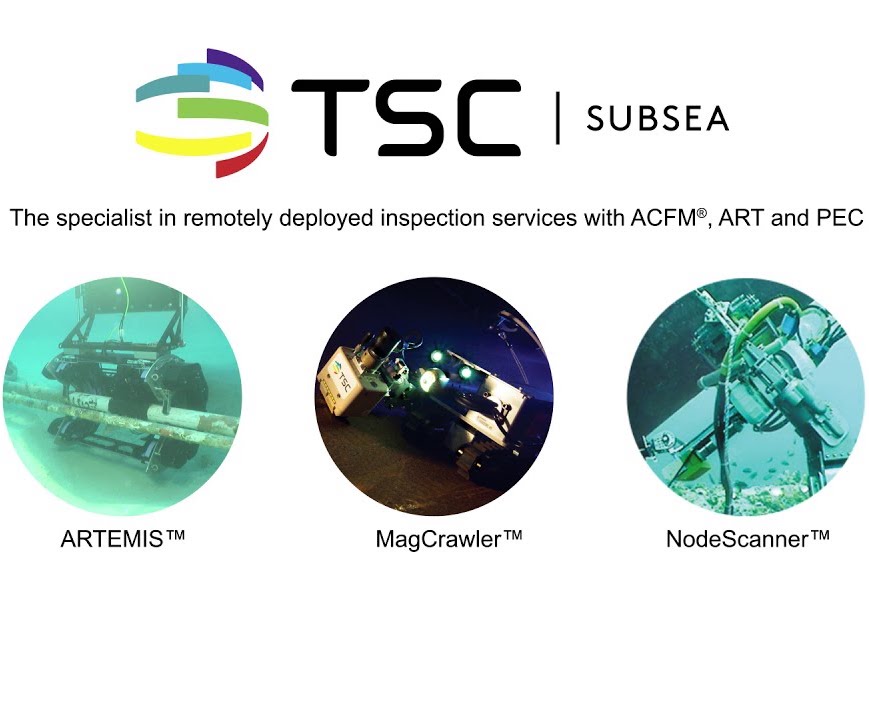

Delivering diverless robotic subsea solutions with our partners, TSC Subsea.

Equipped with human asset of highly motivated management team with wide experience in the energy sector, SubseaRobotix is the exclusive partner to TSC Subsea, a world leader in ROV-deployed subsea Advanced NDT (ANDT) solutions, in Nigeria.

Our Subsea Robotic Inspection Systems

ART

Acoustic Resonance Technology (ART) is used in the detection of weld cracks, corrosion, porosity and variations in density. The technology is deployed to the inspection location subsea using proprietary robotic systems designed for the inspection rigid and flexible risers, flowlines and pipelines, and comes with unmatched coating coating penetration capabilities.

ACFM

Alternating Current Field Measurement (ACFM) is used for the detection of surface-breaking cracks on metallic structures. The technology sizes defect for both length and depth and has a high tolerance for lift-off. The ACFM method is a non-contacting technique that has the ability to scan through coatings, grease and light marine growth thus requiring less cleaning than other crack detection methods.

SPA

Subsea Phased Array (SPA) uses the Total Focussing Method (TFM) to obtain much higher accuracy and resolution from the Phased Array UT technique. The SPA technology is used in the detection of weld cracks, corrosion, porosity, pits and variations in density in materials. TFM minimises the near-surface dead zone and far-surface resolution both of which restrict conventional PA when inspecting ID and OD defects.

SPECTA

Subsea Pulsed Eddy Current Technology Array (SPECTA) is built on the Pulsed Eddy Current (PEC) technique and is used in the detection of wall loss on metallic structures in materials. It provides efficient through-coating assessment and measures relative wall thickness and percentage wall loss across ID and OD. It comes with flexible deployment solutions to suit varied geometry and applications.

We blend our experience and expertise to deploy world-class services.

At SubseaRobotix, we provide an experience that’s not only seamless, but also leaves our clients feeling nothing but confidence in our ability to deliver upon their needs. We aim to contribute towards building the Nigerian capacity to meet the 21st century subsea structural integrity challenges of low cost and quality by delivering the above Robotic Inspection Systems.

How we deliver for our engineering clients.

Consultation &

Assessment

Solution Design &

Engineering

Implementation &

Execution

Monitoring &

Support

Get in touch

We’re glad to discuss your project and to answer your questions. Let’s start the conversation.